Within the sphere of manufacturing procedures, maintaining the stability and output of lines is crucial. Buildup of impurities within pipelines can notably impair flow velocity, weaken yield grade, and inflate preservation fees. To tackle these predicaments, channel scrubbing approaches have arisen as particularly powerful remedies for uninterrupted line scrubbing. A device, mainly a barrel-shaped apparatus, is guided through the pipeline, efficiently cleaning deposits and guaranteeing maximum efficiency

Duct washing procedures provide myriad pros. They are adaptable, prepared for purifying pipelines of heterogeneous sizes and ingredients. Furthermore, they are efficient, fulfilling the operation in a moderately rapid period. By slashing downtime and enhancing pipeline output, pipeline cleaning systems foster expenditure savings and increased operational manufacturing

Hygiene Pigging Techniques:

Sustaining pipeline hygiene is required for supporting item safety and excellence of dispatched assets. Sanitary pigging techniques offer a trustworthy way to fulfill this objectives. Pigs, customized instruments, are inserted into pipelines to sterilize by eliminating residues and contaminants

- Diverse varieties of sanitary pigs are found, each crafted for special cleaning purposes.

- These pigs are constructed from components that meet stringent decontaminated standards.

- Regular sanitary pigging activities promote avoiding product infection, prolong pipeline functional period, and strengthen comprehensive performance.

Leading-Edge Pigging Techniques for Peak Output

pigging productsIn the landscape of channel support, leading pigging technologies have developed into a vital resource for maintaining maximum productivity and protection. These groundbreaking systems exploit clever structures and operations to competently scrub, survey, and shield conduits from degradation. From state-of-the-art pigs equipped with real-time tracking components to focused pigging implements engineered for fine tasks, evolution in this discipline is persistently expanding horizons. By applying these breakthroughs, handlers can markedly increase pipeline stability, curtail downtime, and raise operational efficiency.

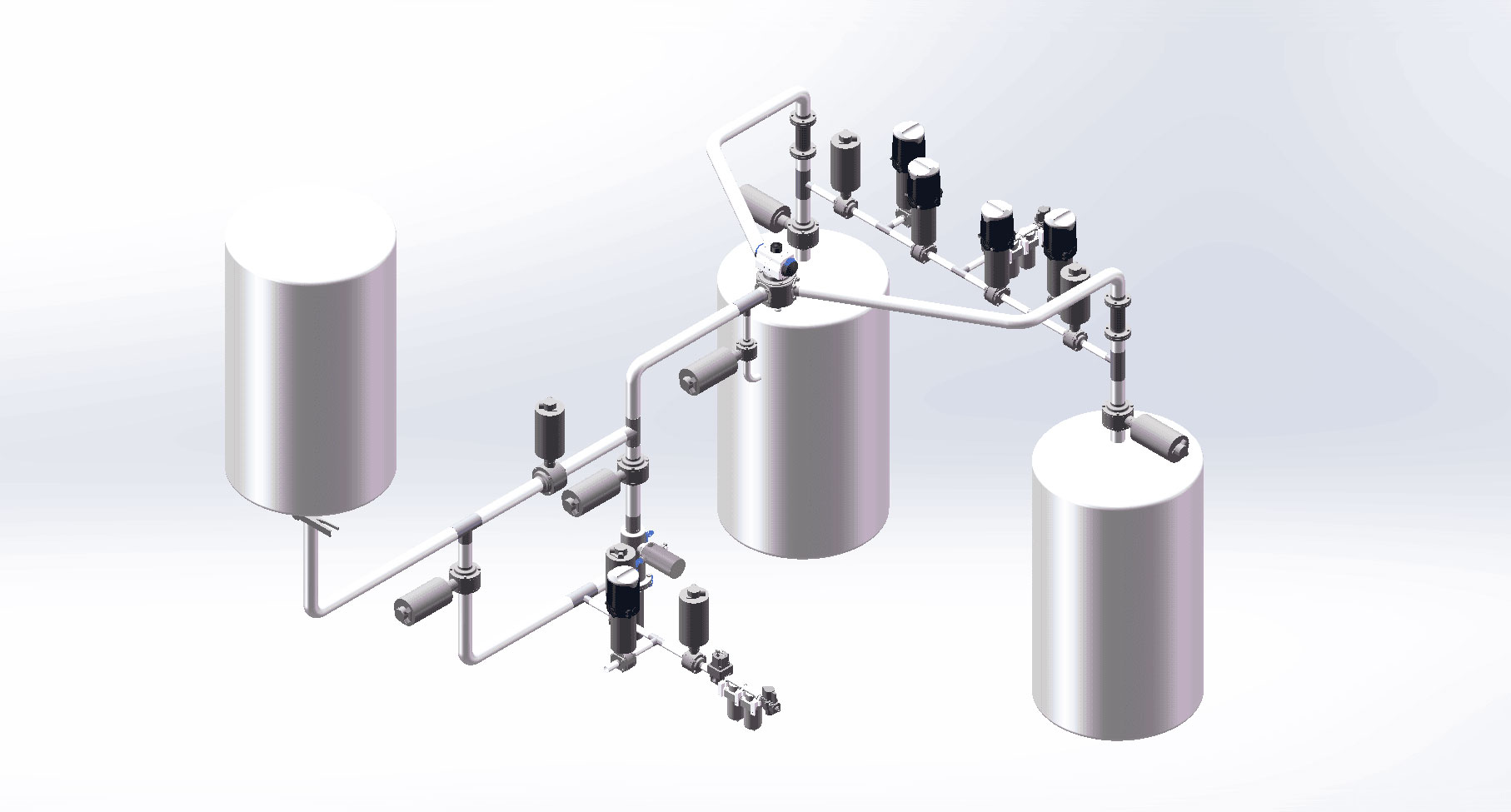

Comprehensive Pigging Configuration Development and Setup

A comprehensive pigging system embodies a fundamental system for pipeline service. This technique involves the insertion of allocated contraptions called pigs, which proceed through lines to sanitize, inspect, and maintain their integrity. The design focuses on components such as line size, material, pig category, and operational requisites. A well-conceived system confirms competent pigging functions while decreasing downtime and potential damages. Installation methods call for careful organization, skilled engineers, and strict adherence to safety protocols to guarantee a risk-free and positive outcome

Mechanical Pigging Equipment for Broad Utilizations

Heavy-Duty pigging tools are necessary implements operated across a extensive group of industries. These products facilitate dependent and efficient purging, examination, and repair of tubes and other duct-shaped assemblies. Pigging embraces placing designed gizmos known as pigs through pipes to handle diverse missions. Popular types of industrial pigging implements incorporate cleaning pigs, inspection pigs, and transfer pigs. Cleaning pigs are built to eliminate debris, build-up, and defilements from pipelines. Inspection pigs are loaded with apparatus that collect information about the shape of pipe shells. Transport pigs are employed to distribute fluids through pipelines. The use of industrial pigging products yields numerous gains, such as minimized downtime, strengthened pipeline sturdiness, and increased operational capacity. These instruments are commonly utilized in markets such as oil and gas, water treatment, chemical production, and food manufacturing.In-Depth Insight into Pipeline Pigging

Pipeline pigging is an fundamental process used within the oil and gas field to monitor pipelines. This fundamental task entails injecting specific devices, called pigs, into the pipe. Pigs are crafted to advance through the length of the pipeline, executing various duties.

Some sorts of pigs are available, each specialized for a particular aim. Common implementations of pipeline pigging encompass auditing for defects, washing, and protective layer application.

- Positive Outcomes of Pipeline Pigging

- Influences on Operational Efficiency

- Classes of Pipeline Pigs

Trusted Sanitation by means of Pigging Methods

Pigging arrangements yield a sound answer for upholding sanitation inside lines. These mechanisms leverage specially designed pigs that operate through the pipeline network, efficiently eradicating layers. The practice is especially rewarding for branches that expect rigorous purity rules. Pigging methods grant a affordable and rapid approach for sanitizing pipelines, reducing the hazard of infection.

Selecting Pigging Instruments for Dedicated Prerequisites

Pigging instruments plays a significant role in productive pipeline management. When opting for pigging instruments, it is critical to consider the specialized prerequisites of your use. This entails considering details such as pipeline girth, flow velocity, product kind, and restoration objectives.

Several pigging choices are accessible, each engineered for distinct reasons. Specifically, some pigs are tailored for reviewing, while others are deployed for extracting residue or separating product shipments.

Also, pigging apparatus constituents should be compatible with the delivered liquid.

It is commonly optimal to connect with a specialist in pigging methods to make certain that you decide on the most fitting apparatus for your distinct needs.

Pipeline Cleaning Arrangements - A Cost-Saving Approach

Pipeline tools offer a considerable selection of virtues for branches using conduits. By smoothly maintaining and monitoring pipe insides, pigging systems improve operational performance and lower maintenance expenses.

A leading asset of pigging systems is their capacity to extract residue such as dirt, debris, and wear particles. This consistent hygiene ensures unobstructed pipeline passage and reduces costly downtime.

Furthermore, pigging systems can be implemented to observe the status of pipelines, revealing potential defects before they develop into major hurdles. This anticipatory technique assists to lengthen service life of pipelines and cut back overall maintenance outlays.

Upholding Hygiene in Pigging Operations

Hog raising schemes rely greatly on appropriate hygiene standards to block the distribution of infections. Following rigorous hygiene measures guarantees a nutritious surroundings for pigs, thus generates better health outcomes and functionality.

Comprehensive cleaning and disinfection of facilities is essential to curb the presence of harmful infectious agents. Satisfactory residues management additionally serves a key part in upholding hygiene.

In addition, {workers